Dust Collector Ducting

Dust collector duct acts as the hose and wand that draws dust away from the machine producing it.

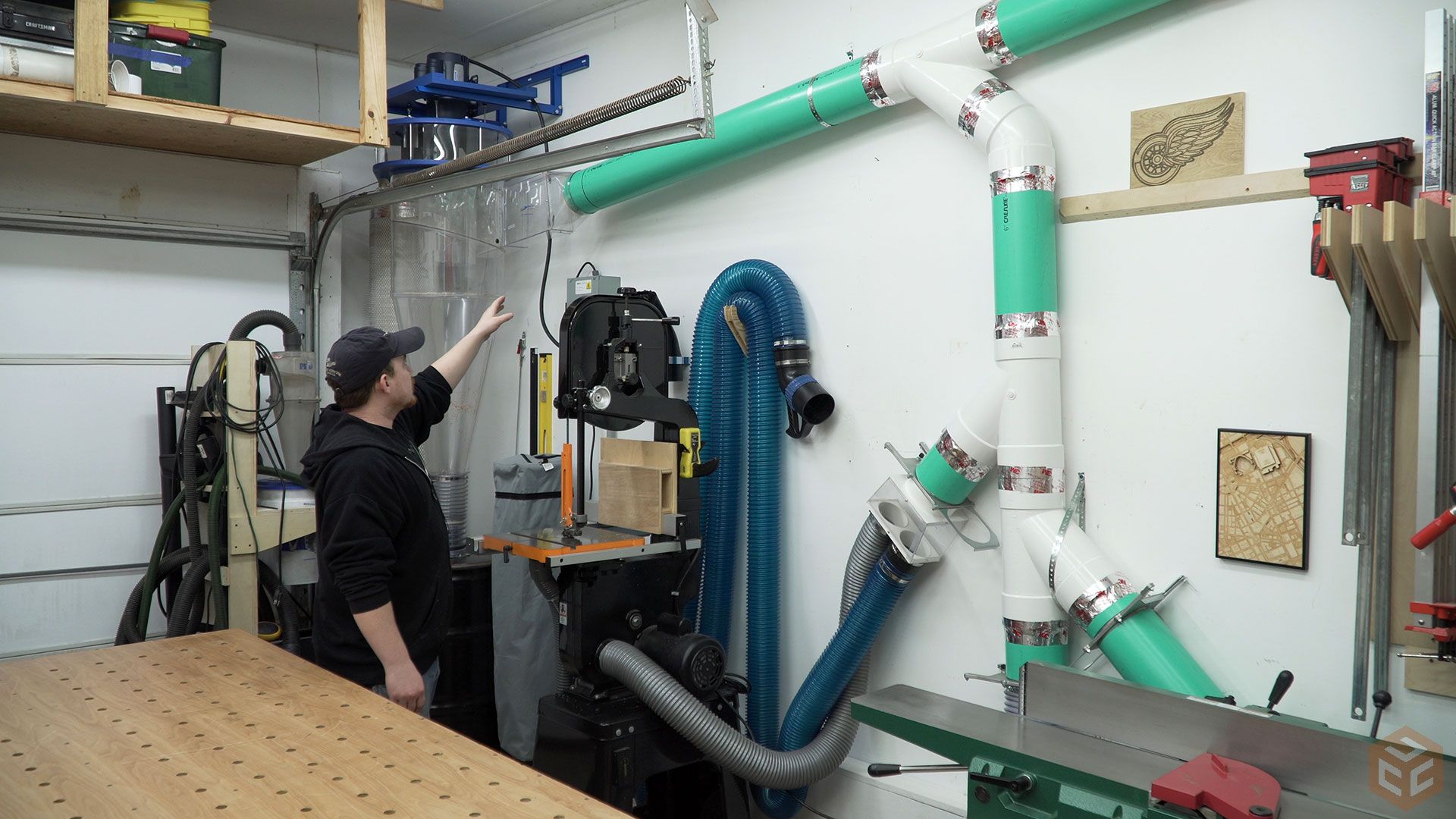

Dust collector ducting. Use these components sold separately to put together a duct system to collect sawdust chips shavings and granular material from woodworking operations. Nordfab ducting can be used in most dust extraction and exhaust air systems almost anywhere there is a dust filter collector baghouse or cyclone cleaning the air. Just because a tool comes with a 4 dust port doesn t mean you should use 4 main ducts or drops. Instead look at the intake port sizes for the collectors you re considering.

What exactly is a woodworking dust collector and why is it so crucial to the success and safety of a woodworking area. Engineered for performance and durability using heavy gauge steel our round sheet metal ducting is built to withstand the high air pressures and constant abrasion created in dust collection and other material handling applications. Most cyclones have intake ports of 6 to 8 and some two bag collectors have 5 or 6 diameter intakes so consider at least a 5 main duct. Do use the largest ductwork that fits your collector.

Choose from our selection of dust collector ductwork including over 375 products in a wide range of styles and sizes. Design your own dust collector duct system. Engineered for performance and durability using heavy gauge steel our round sheet metal ducting is built to withstand the high air pressures and constant abrasion created in dust collection and other material handling applications. The two main types of dust collector ducting are hard fixed used in almost every industrial and commercial application and flexible hose only appropriate for machine connections and other short runs.

Dust particles can affect the quality of a job as the dust can settle into materials being produced. In general the average woodworking dust collector exists for the purposes of making woodworking itself as safe and efficient as possible. Hose clamps are available.